AIRFIX

H.S.Buccaneer S2. S2B

Low level strike bomber

Kit No. 08101. 1:48th scale

AIRFIX

H.S.Buccaneer S2. S2B

Low level strike bomber

Kit No. 08101. 1:48th scale

The kits have been around now for 10 years and I have had them in my loft all this time. Several times I have taken them out and tried to make a start but the warpage on the fuselage halves has made me put them back unstarted, until now.

The kit comes in a nice soft grey plastic and all the parts are nicely detailed with engraved panel lines and recessed rivet detail, the surface of the moulds have not been polished as in most kits these days so there is a sandblasted look on the kit parts but a bit of fine sanding during construction soon takes care of that.

The RAF S2B came out first and was followed by the Navy machine and to this there have been a few improved parts namely the underwing tanks. The RAF tanks came as three separate parts, bottom of the tank and two top halves with pylons attached but the Navy ones have top and bottom of the tank plus the pylons halves as separate items, a vast improvement.

Stores in the RAF kit are, for European ops, tanks and Sea Eagle missiles and for the Gulf theatre, AN/ALQ 101 jamming pod, AN/ALQ 23E pave spike, laser designator pod plus an AIM 9L sidewinder.

Stores on the Navy kit are wing tanks for UK ops and the extended tanks for the South African air force plus bombs and rocket pods.

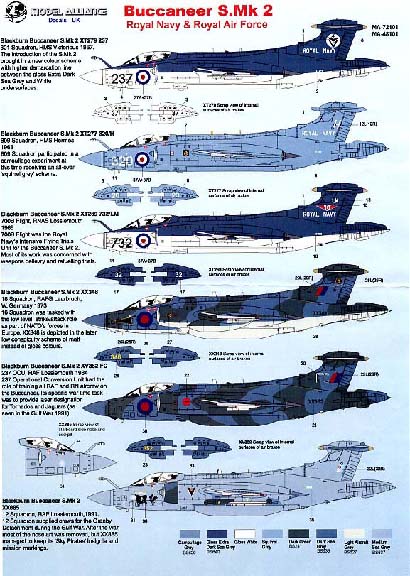

Each kit comes with a huge decal sheet; The S2B Air Force set has markings for a wrap around green /grey scheme for #12 and #208 Sqdns plus a Lossiemouth machine based in the Gulf at Muharraq in the overall “desert pink” scheme, “Sky Pirates” being the machine in question.

The Navy set is for two #809 Sqdn aircraft one in 1970 overall grey with red/white/blue roundels and a later 1976 version with red/blue roundels. 800 Sqdn is also represented with a 1966 grey over white scheme and “A” type roundels, which I chose to make, not forgetting the South African machine with grey over silver finish.

The instructions are in a booklet form and are quite easy to follow with no confusing bits and clear camouflage patterns.

My construction notes.

Usually construction begins in the cockpit but because of the warped halves of the fuselage were so bad in both kits (they were not distorted longitudinally but the bottom half was wider than the top half) I started by cementing the bomb bays to one side of the big hole in the lower fuselage half, this was clamped with clothes pegs overnight and the following day was clamped and cemented to the other side of the hole as well. These were left for two days to harden off while the other assemblies were started and cleaned up.

The seats are a little Spartan but I dressed them up with straps from foil

and masking tape with tiny bits of wire, if you don’t care for that then there are two fine seats available from “Neomega resins” which are a delight and will make all the difference to your model

The HUD part 85 looks too small to me, in fact it looks 1:72nd scale (photo2)so as the base was already cemented in, I cut the clear top glass off and made a new one from 15thou clear plastic sheet slightly larger.

One thing I didn’t like was the wheel to U/C leg arrangement (I can see the reasons behind that fit) so I took note of the position of the wheel in relation to the leg then with some aluminium tubing I made an axle and a “wheel bearing”. (photo3)The original “axles” were cut off the end of each fork which was then drilled out to the new axle diameter and the wheel was drilled to match the new bearing, later when the legs were complete and painted the assembled wheels were mounted making it so much easier to paint both Items.

The intakes, parts 35, were painted white and the fan steel, and before placing in the fairings, part 21/22 the leading edge rings were painted silver, this ensures a neat line between the colours (photo4)

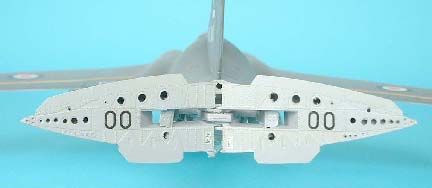

Airfix have made a good representation of those distinctive Bucc’ air brakes but if you want to display them deployed they can be improved upon with the Airwaves PE set # AC48072. Firstly you need to assemble parts 31/33 and32/34 then trim off the upper and lower strakes level with the outer shell then the PE parts can be added and these are spot on with all the holes and dimples where they should be. (photo5)

The next job I tackled was the fuselage halves, The cockpit bath tub was cemented into the top half carefully aligning the moulded ribs, I added the seats and second windscreen later when all the cleaning up was done. I had read Jonathan Mocks article in Scale models Magazine (Jan 96) and I used his method to line up all the joints. Starting at the leading edge of one wing root, along the front fuselage side then back along the other side to the other wing root Taping with half inch masking tape as I went. Then along the rear of a wing and along to the tail and back up the other side also, again taping and clamping as I went,

(photo 6). This was the only way to bring the top and bottom together and this must be left for at least one day to harden.

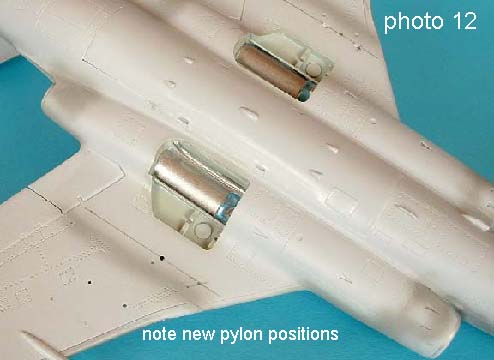

In the mean time the outer wing panels can be assembled bearing in mind the different wingtips for the Gulf war version in the RAF kit and from Jonathon’s review I learned that the navy pylons needed moving inboard, the centre line should be 14mm from the wing fold line and the holes for the inboard pylons/tank should be 6 mm inboard of the same line. (photo 7)

Once the fuselage was cleaned up I added part 12 and 25 and built up some of the internal structure around the airbrake mechanism (photo 8) then I added the wings, intakes and exhaust assemblies. Again the joints needed cleaning up and a little filler added here and there on the wing joint, mine were both assembled in the flying position but parts are provided for the alternative folded position.

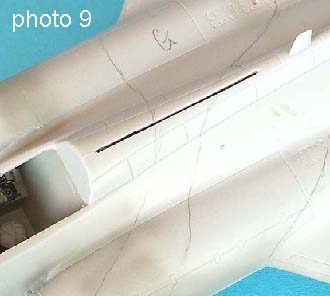

Just behind the cockpit on the spine is a long slot that the canopy guide runs in, I have cut this into the fuselage by drilling a line of tiny holes and joining them up with a scalpel then inserting a fine saw blade to continue the line, once cut a nail file was used to clean up the edges (photo 9). Don’t cut this before assembly as you might break something while under stress.

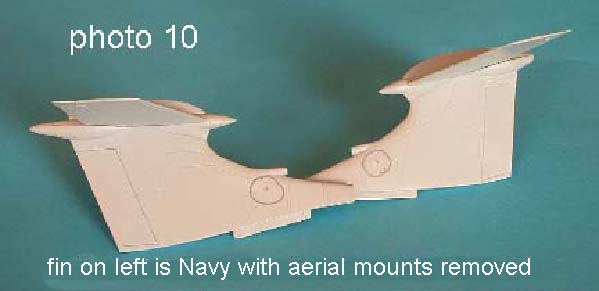

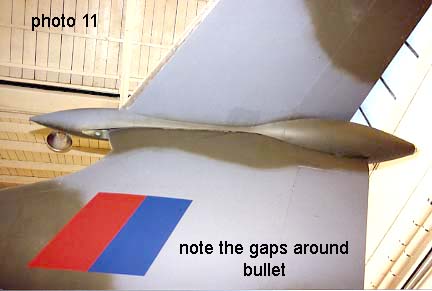

There is a difference between the fins on the two versions; the Navy fin has no aerials fitted so you can fill the holes and sand off the base plates (photo 10), the RWR fairing on the rear end of the bullet needs modification for the option “B” but cut away the tip gradually until you get a good match in diameter. Attach the tailplanes which are a good fit, this is better than the real aircraft which has great gaps around the bullet/fin join (photo 11). Check the fin and tailplanes are all square on the fuselage while the cement sets and leave to harden overnight.

I decided to close the airbrakes on the RAF plane and so before assembling the linkages etc. I cut the strakes from the top and bottom as they are rather thick and when all was assembled I added only one of each back to the centre join line

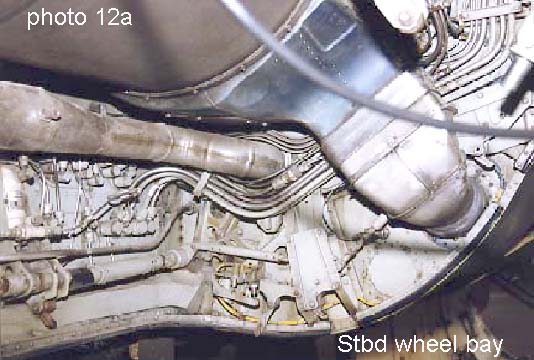

My next job was painting the wheel bays (photo 12) and door interiors and when complete the doors were placed on a blob of Blutack and pressed down in position to mask the area.

I dealt with the canopy at this time also; you will note that Airfix has moulded a frame line across the centre of the canopy which does not exist on the real thing (photo 13), in fact there is a metal bridge on the inside in that position with a packing of some sort to protect the Perspex, I simulated this by painting the inside of the canopy along those frame lines and then the outer surface can be sanded to remove them before polishing back to a clear finish. Both the windshield and canopy were now masked up, the screen was cemented on but the canopy was tacked on with PVA glue to leave it movable later.

Painting and decals

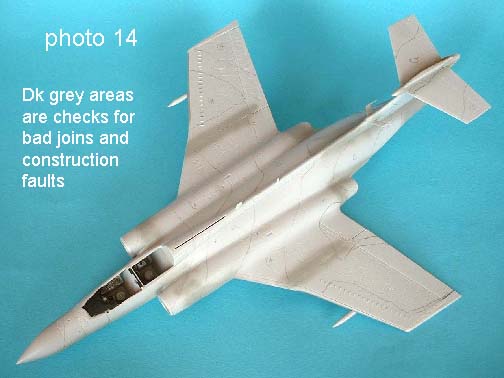

Before painting some Dk grey paint was sprayed on all the joints to make sure the surfaces were good and any imperfections were treated

On the Navy version I sprayed Humbrol Hu130 white, and then masked that to spray the Hu123 extra dark sea grey.

On the Air Force version I used Humbrol Hu164 Dk sea grey, then Hu163 Dk green sprayed on freehand, the demarcations here are very soft, on the real plane I inspected, so I covered this model as close as I could to the original.

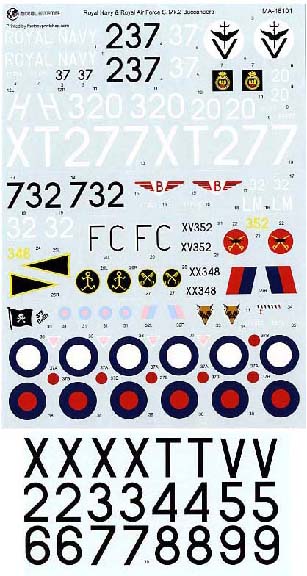

A couple of coats of Johnson’s KLEAR (Future) were sprayed on and left for a day before starting the decal placement. This went fine for my Navy machine but the decals for the RAF model just broke up in the water leaving me desperate but fate smiled on me again at the Southern Expo where Model Alliance decals came to my rescue with a sheet for several Bucc’s, sheet # MA 48101, this gives the various emblems needed and now I have walkways etc. as Airfix came up with a replacement sheetAnother coat of Klear then a final flatting coat, a mix of 3 parts Klear with 1 part Tamiya flat base. Now all the tiny details like Nav lights etc can be painted on and all the masking removed. The canopy on my model was now removed and the seats along with the back seat screen were added. The Blu Tack was removed from the wheel bays and the under carriage was cemented in place and if you remembered to put your nose weight in then it will stand level, if not well….

My Navy model had it’s airbrakes mounted up now, it isn’t too difficult but care and some patience is needed to get it all level and opened evenly.

Pitot tube pylons and tanks are now positioned and small aerials added where needed and there you have it a large scale Buccaneer.

Ted Taylor March 2004

(note canopy is still masked up)