Painting and finishing,

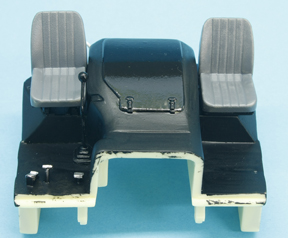

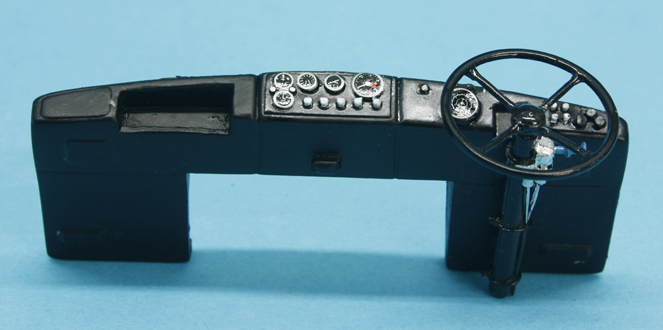

My interior was given a coat of light cream but

light grey would also suit, the metal parts of the door interiors would be the

exterior colour with the “plastic” covered panels semi matt black Hu 85 as would

the engine cover and dashboard , my seats were a medium grey.

Pickfords Blue is not available in the Humbrol

range but Phoenix-Precision paints have it and BRS

red in their “Cherry” range, they are on the web. I sprayed the cab with

a couple of coats of Hu 130 satin white as a base coat and for the roof which I

then masked with Tamiya Tape. The blue was sprayed as a very thin mix and given

a couple of coats to give a good strong colour after which I added a good coat

of Revell #1 gloss varnish and set aside waiting for decals.

The chassis was sprayed with Hu21 gloss black

but the mudguards and fuel tank were sprayed separately to make it easier for

the chassis frame, the wings on the cab were brush painted with the same gloss

black. All the wheels were given a coat of Hu130 white before covering with

bright red Hu19.

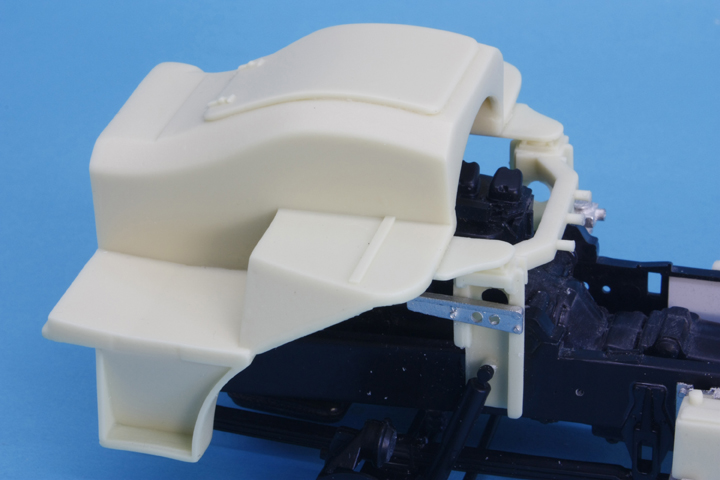

This shows the fire wall as used on most tankers

The trailer

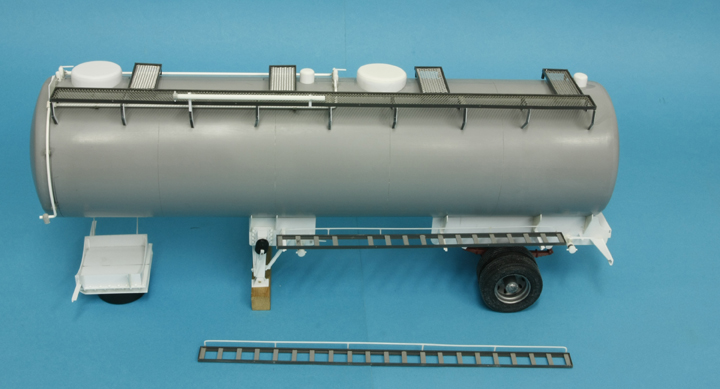

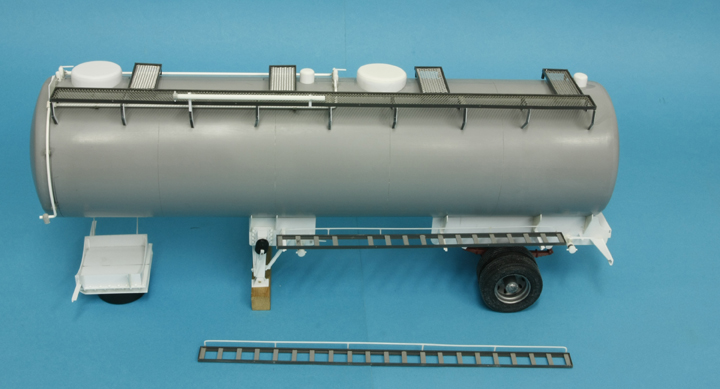

The tank was a 4,000 gallon capacity vessel with

two stainless steel compartments for the carriage of edible oils.

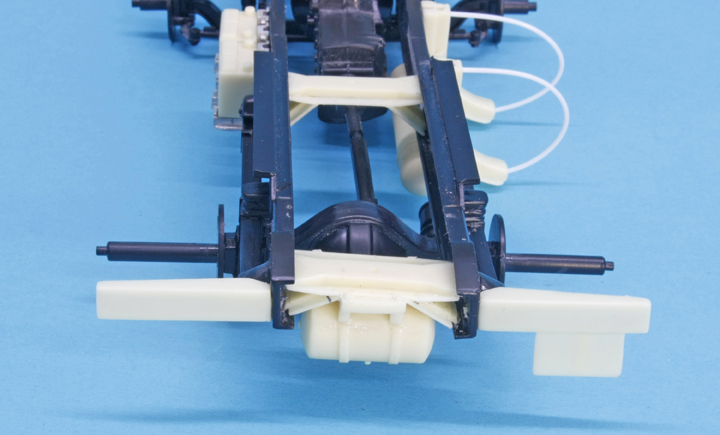

I eventually found the box with the forgotten

tanker model in it and to my surprise all my drawings and notes were there as

well. The tank was constructed but none of the

fittings were made nor was the Chassis so work began in the spares box, first

item to find was an axle and springs I am not sure which kit they came from but

some small alterations made them suitable for my purpose, wheels also came from

the spares box but needed some modification to make a non driven pair. I cut the

extension for the outer wheel off the inner wheel of an Italeri rear set leaving

a flat surface to which a suitable hub can be added then I use an Italeri

“spare” rim to which I add “wheel nuts” from hexagonal rod over each hole this

is then added making sure that the large holes in the rims are opposite each

other so the air valves can be reached.

I eventually found the box with the forgotten

tanker model in it and to my surprise all my drawings and notes were there as

well. The tank was constructed but none of the

fittings were made nor was the Chassis so work began in the spares box, first

item to find was an axle and springs I am not sure which kit they came from but

some small alterations made them suitable for my purpose, wheels also came from

the spares box but needed some modification to make a non driven pair. I cut the

extension for the outer wheel off the inner wheel of an Italeri rear set leaving

a flat surface to which a suitable hub can be added then I use an Italeri

“spare” rim to which I add “wheel nuts” from hexagonal rod over each hole this

is then added making sure that the large holes in the rims are opposite each

other so the air valves can be reached.

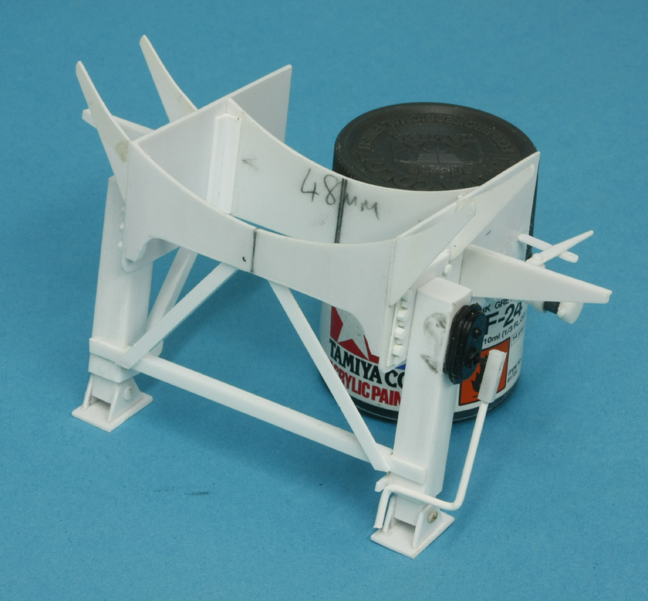

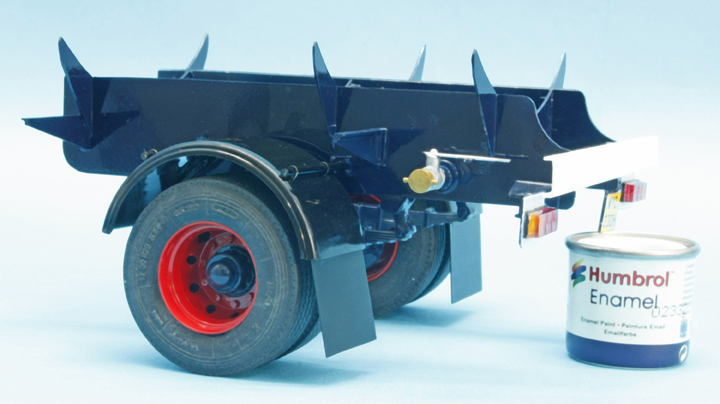

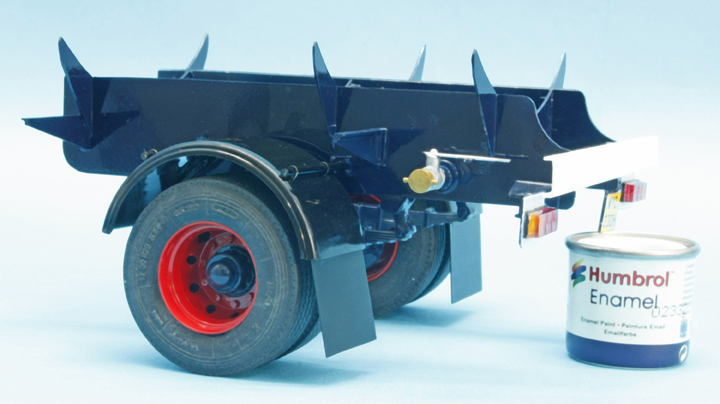

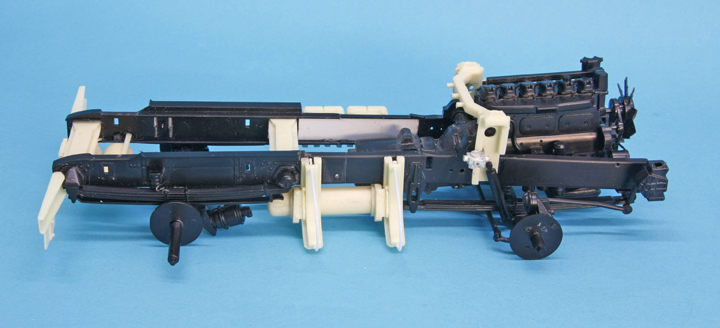

Next job was to make side frames from 40thou

plasticard with cross members and locations for the springs from square fineline

tubing. The side frames were taller than needed and were later adjusted to the

correct ride height.

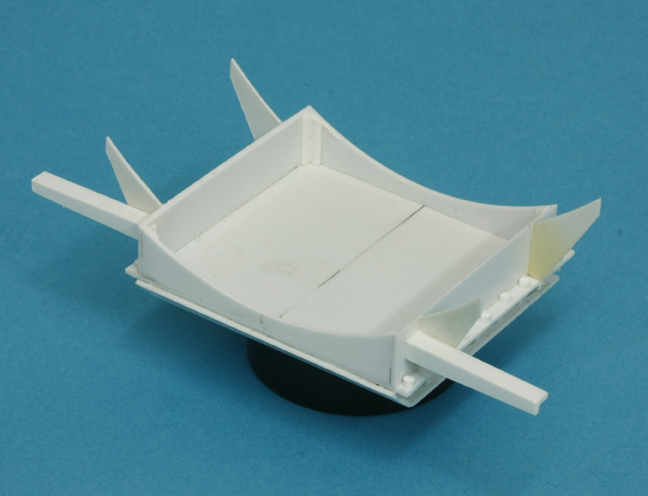

The coupling pin plate was built up from

various thickness plasticard with the nuts and bolts needed cut from Fineline

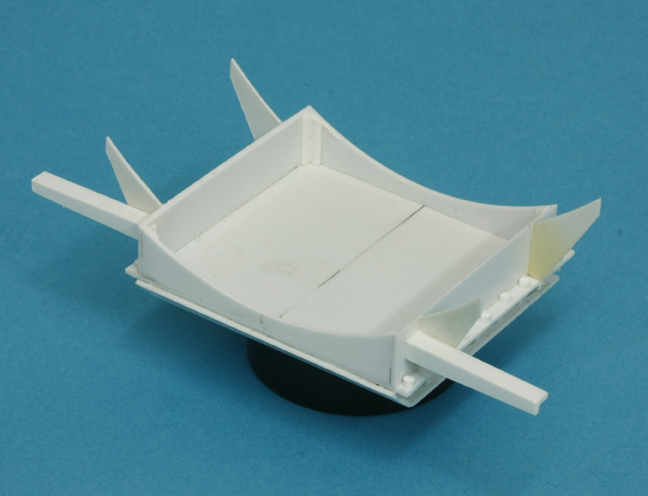

hexagonal rod and cemented in position. All the curved tank supports on

the three major components were made using a spare piece of the tubing left over

from the tank to give the correct matching curve drawn onto tracing paper which

was then laid onto the card and with a sharp point pin pricked the shape onto

the card which was then cut out following the tiny depressions.

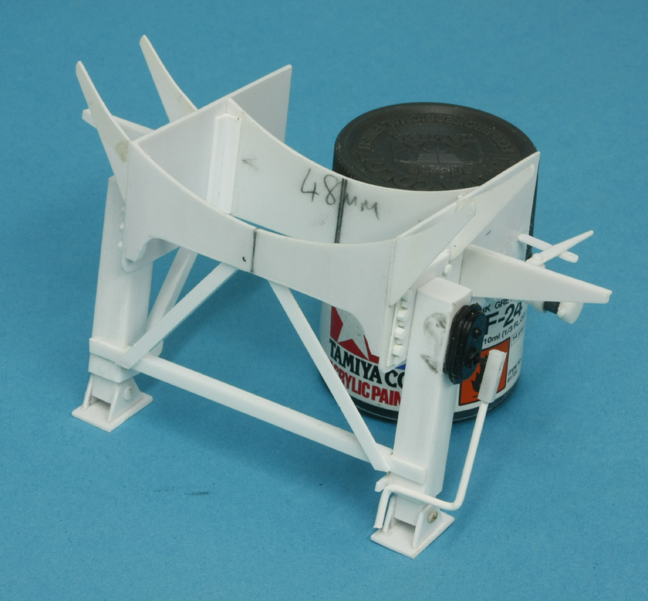

The

legs were built up from two sizes of square fineline tube with angle bracing,

the supports were cut from 40thou card along with the side frames which are

longer than usual because the front outlet is placed there much the same as the

rear outlet is on the running gear frame.

The

legs were built up from two sizes of square fineline tube with angle bracing,

the supports were cut from 40thou card along with the side frames which are

longer than usual because the front outlet is placed there much the same as the

rear outlet is on the running gear frame.

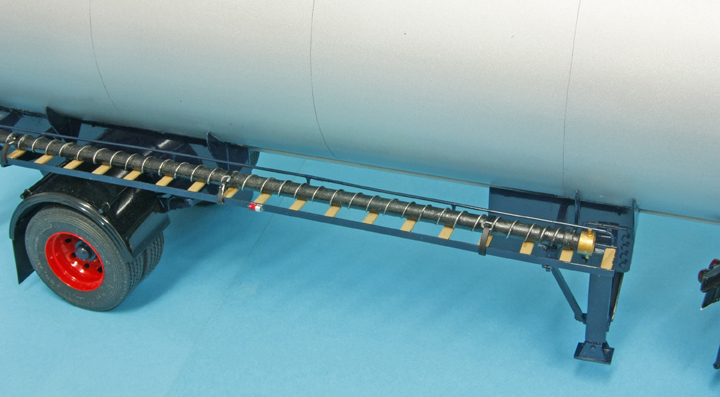

Once the front component was temporarily fitted

the tank was coupled to the unit and the height of the rear side frames adjusted

so there was a slight slope on the tank.

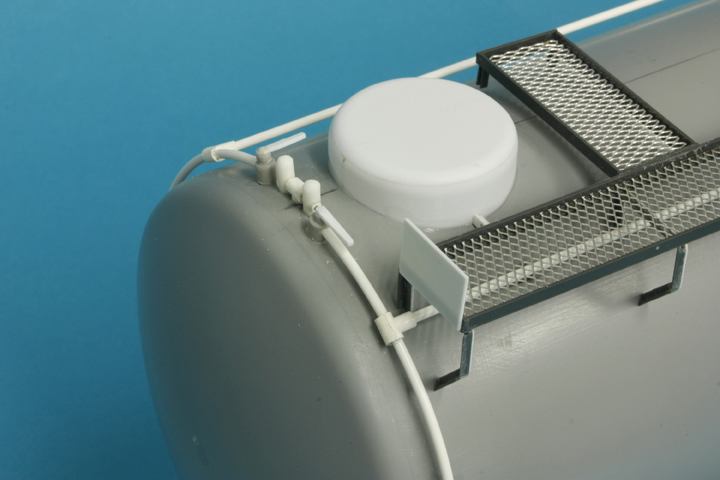

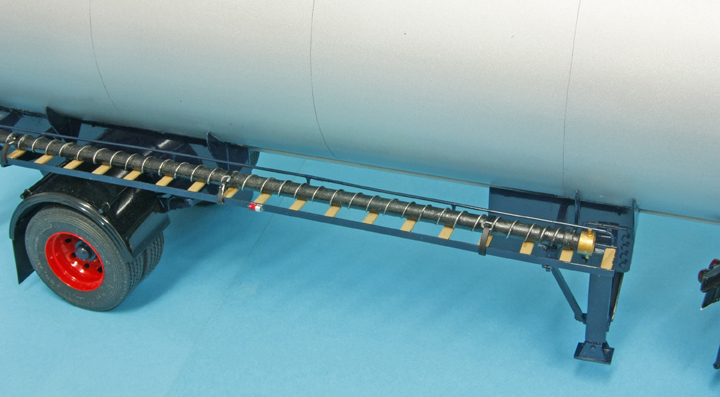

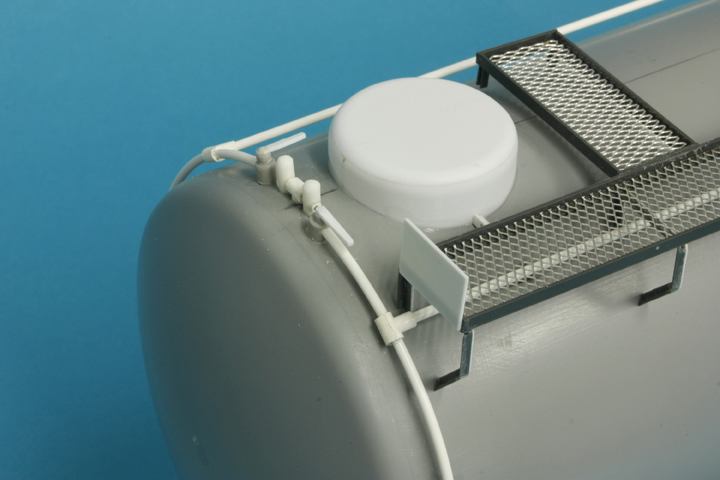

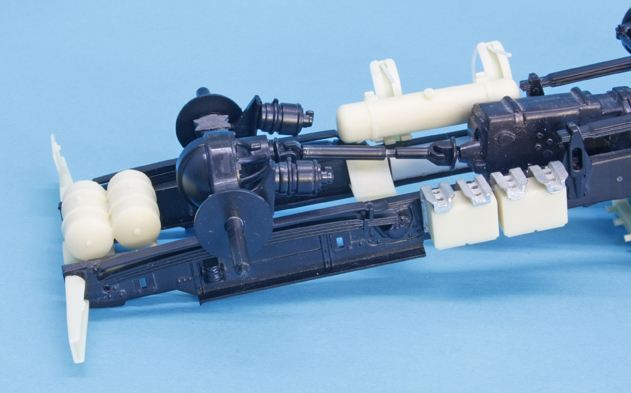

The load in this tank is discharged under

pressure so an air line pipe was formed from Plastruct TB2 tube which has brass

rod inside it and will retain whatever shape is made, the inlet pipe runs up the

left hand side of the tank and into the top of it via a valve and an extension

to the rear compartment via another valve a similar arrangement for the outlet

pipe is on the right side with two safety release valves between the top two,

the clips and “T” joints are also from the Plastruct range.

The load in this tank is discharged under

pressure so an air line pipe was formed from Plastruct TB2 tube which has brass

rod inside it and will retain whatever shape is made, the inlet pipe runs up the

left hand side of the tank and into the top of it via a valve and an extension

to the rear compartment via another valve a similar arrangement for the outlet

pipe is on the right side with two safety release valves between the top two,

the clips and “T” joints are also from the Plastruct range.

To make the two man hole covers I cemented a

strip of 20thou card around an 80thou disc then another 80thou disc, slightly

larger, was added to the top and left to harden. The covers for the foot valves

(the two small lids) had a disc cemented to a piece of small tube, later the

shoulders of these four items were sanded to a rounded shape to give a domed

effect. The lower edges of the lids were shaped to match the tank by wrapping a

sheet of sandpaper around the tank and rubbing them back and forth on it until

they fitted.

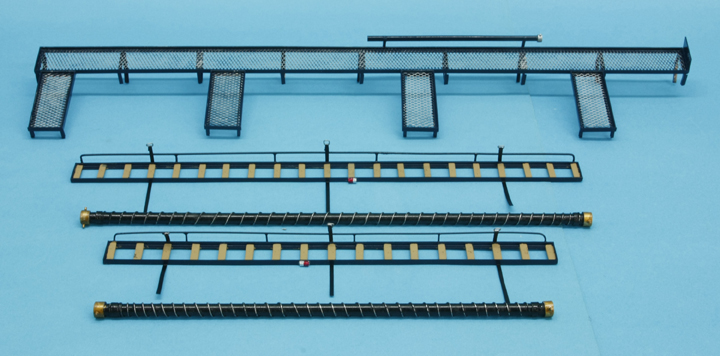

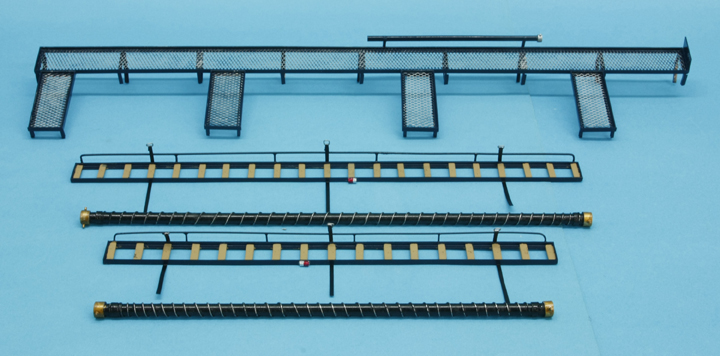

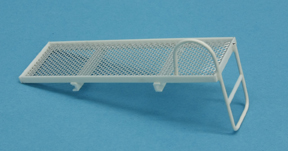

The catwalk was made using A3 angle and expanded

mesh similar to that on the unit with the supports from A2, a tube for the

dipsticks was fashioned from fine tubing and mounted on the side while the

ladder was made from a length of TB1 bent into a long “U” shape with steps from

bits of 40thou plastic rod. Hose racks are needed on both sides and these can be

made from A3 angle but this time fill the centre with lengths of 3mm strip to

represent the wooden battens on the real thing. Hoses can be made from tubing

with fine lead wire wrapped around and couplings from odd bits of tube added on

the ends.

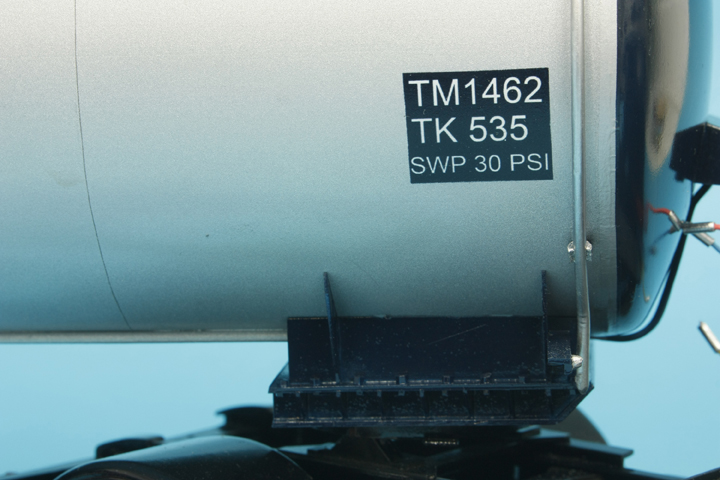

Painting and finishing,

the three main components, the covers and the ends of the tank were sprayed blue

separately then the tank ends were masked off and Humbrol matt aluminium from

the Metal Cote range was sprayed on the main body and pipework, later a coat of

Johnsons Klear was added to seal it.

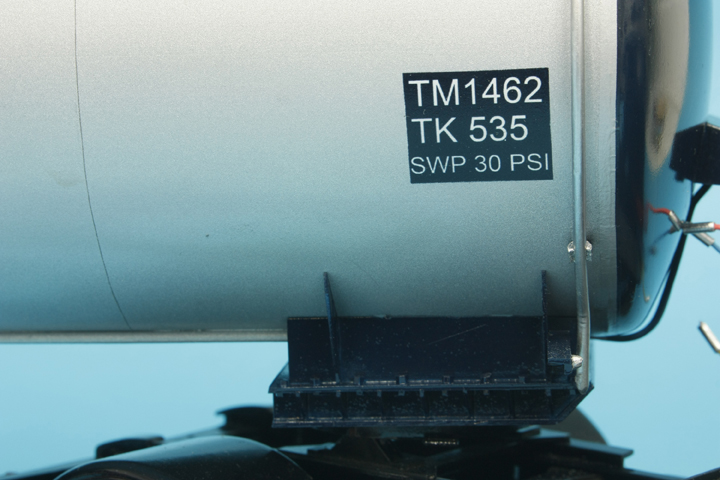

All the components were fitted using epoxy resin

for extra strength and to avoid disturbing the paint, once they were on the

discharge pipes and valves were made from scrap rod, pipe and strip then

positioned before placing the hose racks on the brackets. All the usual

furnishings for a trailer were built from scrap plasticard such as rear light,

reg plate plus front sidelights arms and a box for the suzie couplings on the

front. My decals were made on a computer using Experts-Choice white decal paper

from Bare Metal Foil Co.

All in all a very satisfying model of one of my

old trucks brought to a conclusion after 30 years in hibernation.

Ted Taylor

Aug 2009

#Back to the Top

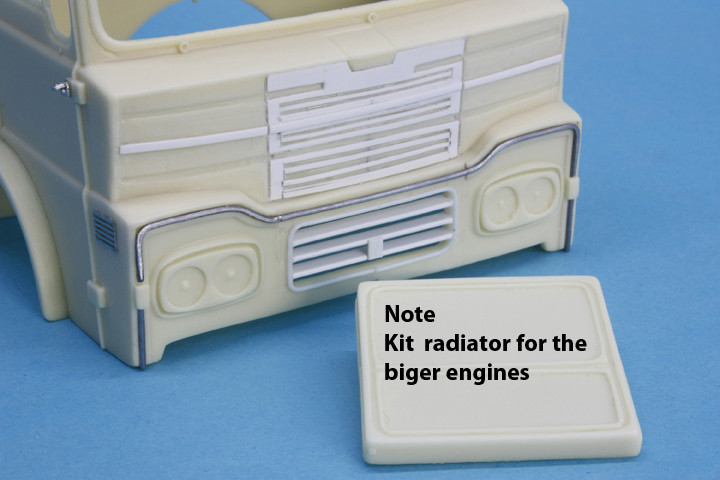

My first job was to sand/scrape off the two air vents at the sides of the grille and then scrape out the top centre section deep enough to lay a sheet of 20thou plasticard in there. The centre panel on the real truck is removable so I made the card just a tiny bit narrower than the space available to give a “panel line“ effect this was then carefully marked and cut to represent the grille before being glued into the centre.

I eventually found the box with the forgotten

tanker model in it and to my surprise all my drawings and notes were there as

well. The tank was constructed but none of the

fittings were made nor was the Chassis so work began in the spares box, first

item to find was an axle and springs I am not sure which kit they came from but

some small alterations made them suitable for my purpose, wheels also came from

the spares box but needed some modification to make a non driven pair. I cut the

extension for the outer wheel off the inner wheel of an Italeri rear set leaving

a flat surface to which a suitable hub can be added then I use an Italeri

“spare” rim to which I add “wheel nuts” from hexagonal rod over each hole this

is then added making sure that the large holes in the rims are opposite each

other so the air valves can be reached.

I eventually found the box with the forgotten

tanker model in it and to my surprise all my drawings and notes were there as

well. The tank was constructed but none of the

fittings were made nor was the Chassis so work began in the spares box, first

item to find was an axle and springs I am not sure which kit they came from but

some small alterations made them suitable for my purpose, wheels also came from

the spares box but needed some modification to make a non driven pair. I cut the

extension for the outer wheel off the inner wheel of an Italeri rear set leaving

a flat surface to which a suitable hub can be added then I use an Italeri

“spare” rim to which I add “wheel nuts” from hexagonal rod over each hole this

is then added making sure that the large holes in the rims are opposite each

other so the air valves can be reached.