AMT/ERTL/Paragon

S-3B VIKING

1/48th scale Kit No. 8634.

Paragon latest releases

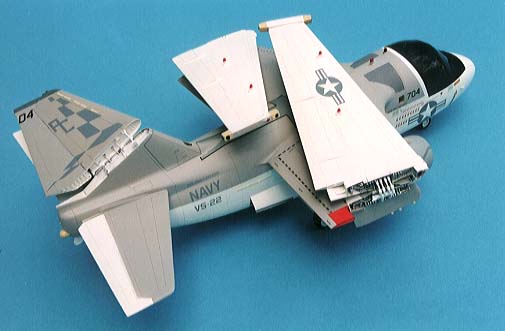

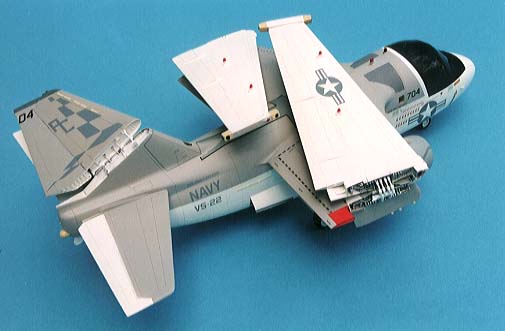

S-3 Viking wingfolds and finfold

Price £12.99

The parts (the colour of the resin is yellow)

S-3A/B Viking with folded wings

AMT/ERTL/Paragon

S-3B VIKING

1/48th scale Kit No. 8634.

Paragon latest releases

S-3 Viking wingfolds and finfold

Price £12.99

The parts (the colour of the resin is yellow)

S-3A/B Viking with folded wings

The ESCI kit has been a favourite of mine for many years now, firstly it is easy to put together, secondly it is easy to paint and thirdly the cockpit and canopy can be fitted last of all, making life so much easier.

Construction can start with the fuselage, if you are using the tail fold then now is the time to cut the fin/rudder from the main parts, exact dimensions are given so stick to them. After locating the “mad” boom into it’s bracket and engaging the tail hook (you may have to drill out the locating holes here) it can be mounted into the fuselage half and the two halves closed up, cemented and clamped or taped to harden. The nose wheel bay goes in next but is a loose fit and to get over this problem, when adding some nose weights which I fix with epoxy resin, I run a bead of it around the bay on the inside to seal the joins, it will find it’s own level and needs no sanding afterwards.

On the models I have built before I have always left the FLIR bay doors and main crew entry door open but with the wings folded that would be an unlikely scenario so both were closed as were the bomb bay doors, the fit of these is not the best and I had to use strips of 15 thou plasticard to fill the gaps and make sure they were level with the surface.

The main gear bulkheads were positioned and cemented and in this case the undercarriage legs were added. The kit legs are a bit delicate so I used the white metal set from Aeroclub “SET V170”These are much stronger and will not bend, if I were making an all over grey machine the legs would not be mounted yet, the bays would be sprayed white and the doors temporarily put in position with a blob of Blu Tac to mask off the bay while the grey is sprayed on.

The tailplanes and sonobouy panel can be added to the main fuselage and the joins cleaned up now but the wings need attention before they can be constructed. Paragon’s instruction sheet give exact dimensions again here and I cut just short of the mark and sanded back carefully to my line, instead of trying to make complicated bits to fit the wing fold itself you just cut straight across the wing in two places and you get resin “end caps” to butt join to the two wing sections, simply cut off the pour blocks from each part and stick them on the ends don’t try to make the pour block fit the wing cavity it’s much too fiddly and time consuming.

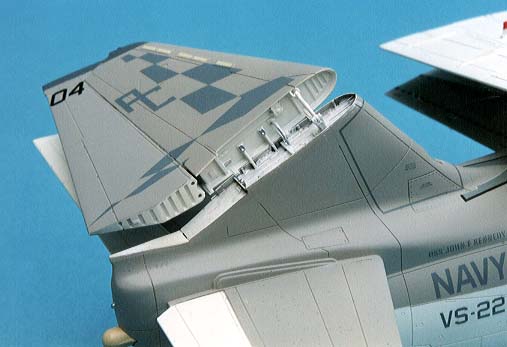

Fit the inner wing to the fuselage and then build up the fin, it isn’t mentioned in the Paragon instructions, but before the fin is folded the rudder gets a 15 degree kick to the right so when the two halves are set hard cut the rudder off using several cuts with a strong blade and reset it to the right a bit by sanding one side slightly. Level off the edges of both sections and add the resin parts to each section ready for painting.Build the engines up but don’t add the bypass fans (part 2) to the engine assembly, add it to the cowl sections with the front fan, make sure that the fans location slot is at exactly 9 o’clock position level with the tiny pin on the cowl to ensure the engine is the right way up, this makes it easier to clean up the joins and simplifies the painting.

The cockpit can now be treated add what ever suits your requirements ready for painting, add all the little antenna after cleaning up the fuselage joins and let us spray. I have used Humbrol Hu 130 for the white areas sprayed on freehand; this was left overnight while I painted the cockpit.

Next all the white areas including the strip around the rear of the cockpit were masked with Tamiya tape and the grey FS 36440 was sprayed on. The canopy windows were masked and sprayed with Humbrol 85 satin black then all the masking was removed and the paint left for a day to harden. A coat of Johnson’s Klear (Future) was brushed on to all surfaces then rubbed over lightly with a well worn piece of wet and dry before adding the decals, I used SuperScale sheet No48-421 a low viz markings set on a high viz paint scheme. These were in turn coated with Klear.

Adding the outer wing sections needs care; I interlocked the hinges and supported the tips with a pillar of Blutac at the correct angle appx 10 degrees then superglued the hinges and added the remaining tiny linkages. The tail fin I treated differently, a tiny hole was drilled in both halves and a piece of florists wire was inserted between the two and the fin bent over to right angles then superglued in position still supported by the wire.

Lastly the cockpit and canopy were added, the engines built up and mounted along with the pylons and instrument probes then the wheels and gear doors were added to finish the job.

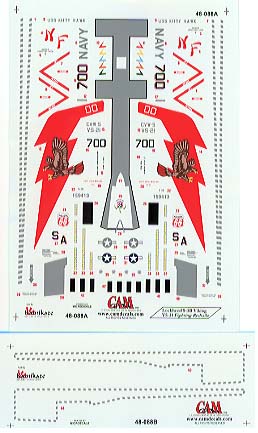

Paragon also does a slats and flaps set for the Viking and I have used these along with the new decal sheet from CAM decals for VS-21. This time the job is fairly straightforward it is just a case of cutting the kit flaps off and replacing them with new interior wing spars and hanging the flaps on, very simple. My method of mounting the flaps is to add four lengths of florists wire to each flap where the screw jacks would be and drill matching holes in the spar, then push the wires into the holes and bend the flap down to the required angle, the holes must be a tight fit though you can then adjust to suit.

Two fine models that are just that little bit different

| Last

Page |

Airbase |

What's New |

Home |

Reviews |

Next Page |